Warm Welcome to China University of Geosciences' Beautiful Hebei Evaluation Experts for Their Inspection Visit to Remei

Building a "Zero-Waste City" to Contribute to Beautiful Hebei

To thoroughly implement the spirit of the 20th National Congress of the Communist Party of China and fully carry out the deployment requirements of the 10th Provincial Party Committee Plenary Session, efforts are being made to achieve modernization featuring harmony between humanity and nature, accelerating the construction of a beautiful Hebei with blue skies, green lands, and clear waters. Relevant departments have proposed coordinating industrial restructuring, pollution control, ecological conservation, and climate change response, synergistically advancing carbon reduction, pollution reduction, green expansion, and growth, and taking landmark actions to create a Hebei scenario for Chinese-style modernization.

On August 30, the Beautiful Hebei evaluation expert team from China University of Geosciences visited Hebei Remei Polymer Materials Co., Ltd. for research and inspection. Li Junjiang, General Manager of Hebei Remei Polymer Materials Co., Ltd., and heads of relevant departments accompanied the delegation.

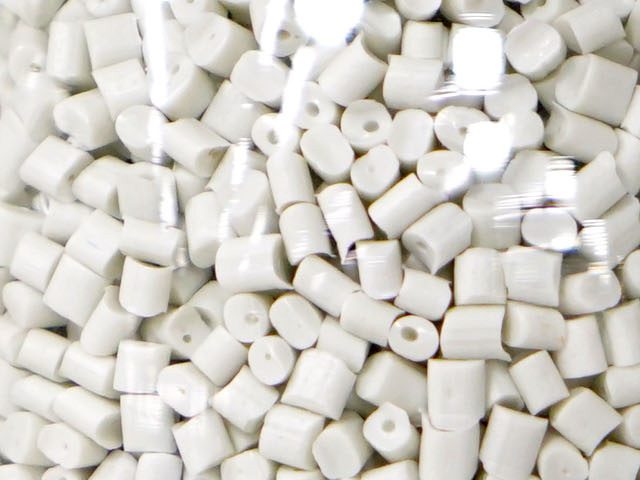

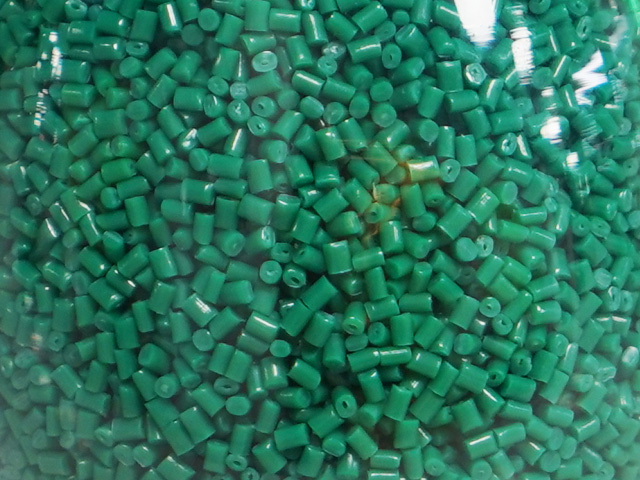

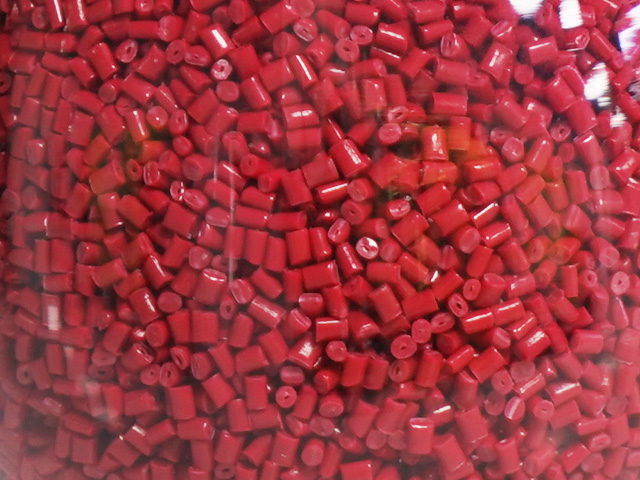

Driven by a strong sense of social responsibility to reduce plastic pollution and accelerate the construction of a waste recycling system, Hebei Remei Polymer Materials Co., Ltd. was established with the corporate mission of "Creating a Better Life Through Recycling," specializing in the research, development, and production of food-grade recycled high-density polyethylene (RHDPE) plastic pellets.

Led by General Manager Li Junjiang, the expert team visited Remei's corporate culture exhibition hall, production workshops, and laboratories.

Li Junjiang explained that to address the two major challenges hindering the high-quality development and high-value utilization of recycled plastics, Remei has continuously invested in research and development, successfully increasing the content of recycled high-density polyethylene plastic pellets in blow-molded products to over 40%. The product quality meets food-grade standards and can be widely used in film blowing, blow molding, pipe extrusion, wire drawing, and other fields.

The expert evaluation team highly praised and affirmed Remei's factory environment, production equipment, and business model.

Remei's Dingzhou plant represents a total investment of 120 million yuan, covering an area of 40,200 square meters and equipped with 15 internationally advanced crushing, washing, and pelletizing production lines. The annual production capacity reaches 100,000 tons of RHDPE plastic pellets, with an annual output value of 575 million yuan.

Additionally, Remei has established an independent polymer materials research center and formed collaborative partnerships with several renowned domestic universities. To date, the company has applied for over 40 patents and developed independently intellectual property-protected recycled pellet production lines.

Currently, Remei's Dingzhou plant processes 300 tons of waste plastic daily, making it the largest recycled plastics enterprise in the Beijing-Tianjin-Hebei region in terms of daily processing capacity. It covers the recycled small and medium-sized hollow container market in the area, significantly improving the recycling efficiency of HDPE plastic products.

Beyond focusing on technological R&D and production, Remei actively responds to national calls, exploring new development models for the recycled plastics industry under the green circular economy framework. By comprehensively integrating upstream and downstream industrial chains and continuously increasing the recycling rate , the company has built a recycled plastics ecosystem serving over 100 million people in the Beijing-Tianjin-Hebei region.

Moving forward, Remei will continue to uphold its corporate mission of "Creating a Better Life Through Recycling,promoting the green, circular, reducing plastic pollution, protecting the environment, and contributing to the achievement of China's "carbon peak" and "carbon neutrality" goals.

Leave a reply