The Green Journey of Recycled HDPE:REMEI POLYMER's Mission and Commitment

In 2004, as China emerged from the shadow of the SARS outbreak, a wave of recovery and ambition swept across the country. A young entrepreneur in his early twenties, driven by a passion for environmental protection and a vision for sustainable business, founded a service platform dedicated to waste material recycling. Through years of dedication and meticulous effort, the company expanded, diversifying its products and services—giving rise to the brand “ReplasTech.” In this journey of growth, the “Zhongfeitong” Group also took shape, carrying forward a sense of social responsibility and environmental mission.

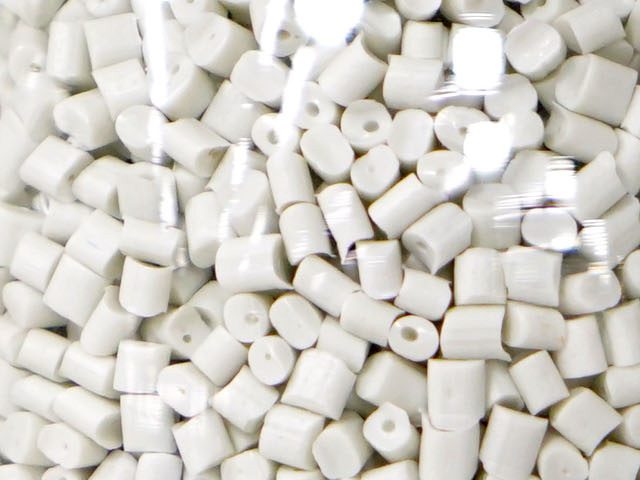

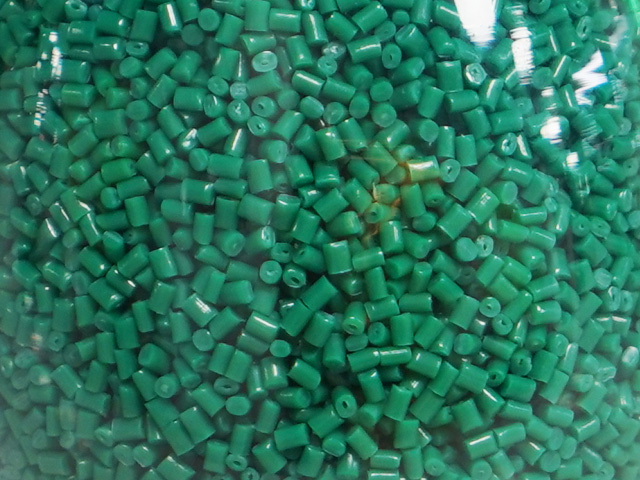

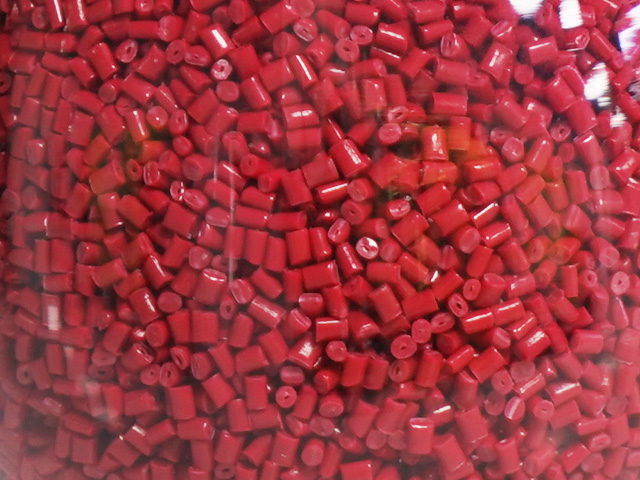

In 2020, powered by technological innovation, we transitioned from solely producing recycled pellets to offering a full-chain service covering “collection, sorting, cleaning, modification, and testing.” To strengthen our production capacity and quality assurance, Remei Polymer invested 120 million RMB in building a digital smart factory spanning 40,200 square meters. Equipped with 15 internationally advanced fully automated production lines for crushing, cleaning, and pelletizing, and recognized as an AAA credit-rated enterprise for our compliant and transparent operations, we established an efficient and traceable recycled HDPE production system. Additionally, through our independently established Polymer Materials Research Center, we formed a core R&D team led by over ten senior polymer technicians. By collaborating with multiple domestic universities, we have achieved more than 40 patented technologies, continuously tackling key industry challenges such as performance optimization and process enhancement for recycled materials.

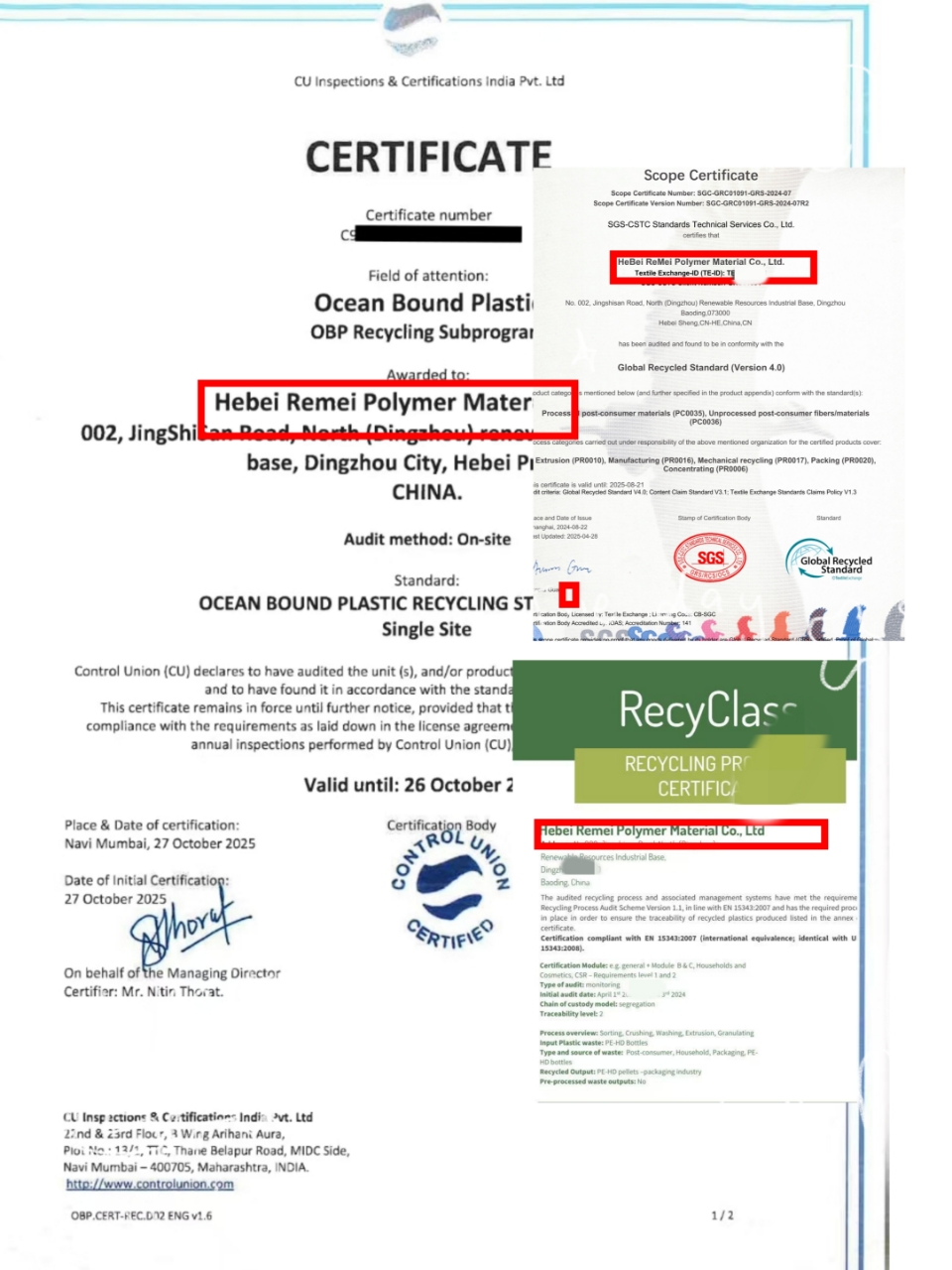

As a leading producer of high-quality recycled HDPE in China, we understand the stringent certification requirements in this field. After undergoing rigorous audits, we successfully obtained three major international certifications: GRS (Global Recycled Standard), OBP (Ocean Bound Plastic Certification), and Recyclass (European Plastics Recycling Certification). Complemented by an eight-step strict testing process in our CNAS-accredited laboratory, we ensure every batch of products not only delivers consistent performance but also fully complies with international standards such as EU REACH. This provides solid support for the sustainability strategies of our European clients. Our relentless pursuit of quality and compliance has transformed us from a regional workshop into a source manufacturer with an annual capacity exceeding 100,000 tons. Our products are now used in high-end pipeline engineering in Germany and food-grade packaging in Europe, challenging the industry misconception that “recycled materials mean lower quality.”

Today, our environmental footprint extends across more than 20 countries and regions, including Europe, America, and Southeast Asia. We have established long-term, stable partnerships with hundreds of globally renowned pipeline and packaging companies. Yet, what remains unchanged is our original environmental mission: producing one ton of recycled HDPE reduces carbon emissions by 1.8 tons and saves 800 liters of crude oil. We firmly believe that long-term business success is inseparable from environmental sustainability. This conviction is both our responsibility as an industrial enterprise and the core driving force behind our ongoing efforts.

From a humble workshop to an industry benchmark, from a promise rooted in purpose to trust from the global market—Remei Polymer’s next chapter in sustainability will continue to be guided by our environmental mission, supported by technology, powered by our digital smart factory, and assured by international certifications. Together with global partners, we strive to harness the circular potential of recycled HDPE, illuminating more possibilities for sustainable development and contributing to a greener, brighter future for our planet.

Leave a reply