From Waste to Value: Building a Circular Plastics Ecosystem for Over 100 Million People

As the Chinese New Year approaches, it is a moment not only for renewal, but also for reflection.

Around the world, the concept of a circular economy has moved from vision to consensus.

Reducing waste, lowering carbon emissions, and improving resource efficiency are no longer optional — they are structural requirements for sustainable growth.

In China, this transition is now firmly embedded at the national level. The 14th Five-Year Plan for Circular Economy Development defines circular economy as a core development strategy, linking it directly to resource security and the country’s carbon peaking and carbon neutrality goals.

But policies alone do not create impact.

Only real industrial execution does.

Why Recycled Plastics Matter

Plastics are among the most widely used materials in modern society — from daily packaging to construction, transportation, and infrastructure. Polyethylene (PE), in particular, is the most produced and most consumed polymer globally.

China is both a major producer and a major consumer of polyethylene. That scale also means something else:

an enormous opportunity — and responsibility — to improve post-consumer recycling and material reuse.

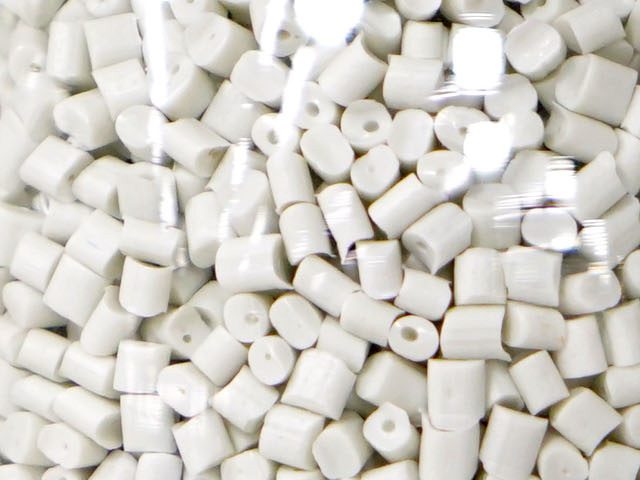

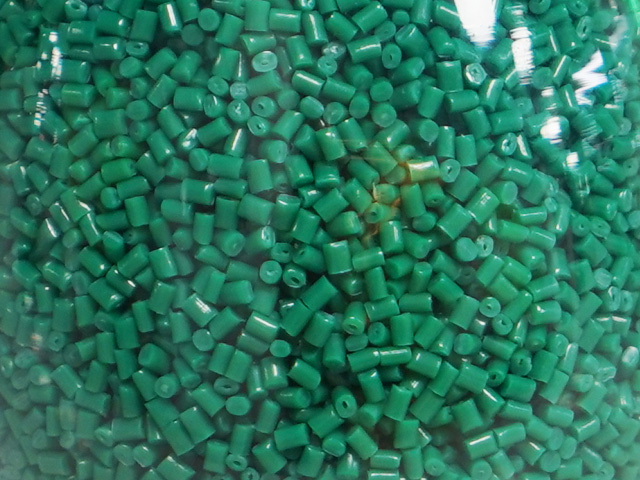

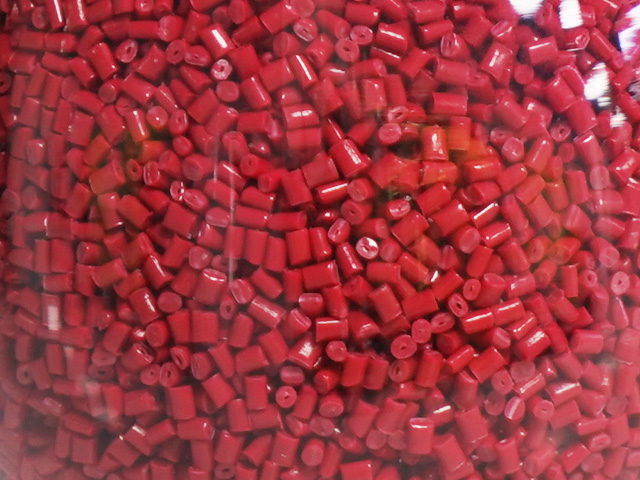

Recycled plastics are a critical pillar of the circular economy. Through collection, sorting, washing, reprocessing, and material upgrading, plastic waste can be transformed back into high-quality raw materials and reintroduced into industrial applications.

The challenge is not recycling in theory, but recycling at scale, with stability, and with quality.

Our Focus: Food-Grade rHDPE and Closed-Loop Recycling

At Hebei ReMei Polymer Materials Co., Ltd., we chose to focus on recycled high-density polyethylene (rHDPE) — one of the most widely used yet most challenging recycled materials to upgrade.

To push the boundaries of what recycled plastics can achieve, we established a dedicated Polymer Materials Research Center and built an R&D team of more than 10 senior polymer engineers.

After years of technical development, we achieved stable, large-scale production of food-grade rHDPE pellets, enabling recycled content levels of over 40% in blow-molded products.

This makes true “bottle-to-bottle” closed-loop recycling not just a concept, but a commercial reality.

Building a Smart Factory — and a Full Circular Ecosystem

Technology alone is not enough. Scale matters.

We invested RMB 120 million to build a 40,200 m² digital smart factory, equipped with 15 internationally advanced crushing, washing, and pelletizing lines.

Today, ReMei holds 40+ national patents and operates a proprietary recycled plastics production system with independent intellectual property.

More importantly, we are actively integrating upstream and downstream partners to build a full lifecycle circular system covering:

Collection → Recycling → Pelletizing → Application

Our Dingzhou facility processes 300 tons of post-consumer HDPE waste per day, covering small hollow HDPE waste generated by over 100 million people in the Beijing–Tianjin–Hebei region.

- Annual rHDPE output: 100,000 tons

- Annual production value: RMB 575 million

- Applications: blow molding, films, pipes, extrusion, fibers, and more

This is not just capacity — it is systemic circular infrastructure.

Recognized, But Still Moving Forward

On June 5, 2023 — World Environment Day — China Central Television’s Economic Half Hour featured ReMei in a special report on circular economy development, highlighting our role as a representative enterprise in China’s recycled plastics industry.

We see this not as an endpoint, but as encouragement to go further.

Looking Ahead

Our mission remains clear: “Creating a better life through recycling.”

As we step into a new year, ReMei will continue to invest in:

- higher-quality recycled materials

- deeper industry collaboration

- scalable circular economy models

By reducing plastic pollution and lowering carbon intensity across the value chain, we aim to contribute — in real, measurable ways — to global sustainability and China’s dual-carbon goals.

The circular economy is not built overnight.

But it is built — step by step — by companies willing to take responsibility and commit for the long term.

Leave a reply